See Inside: The GKN Wheels factory in Telford

GKN Wheels & Structures has recently completed a significant investment programme at its Telford plant that resulted in production output being tripled. We take a look inside and explore some of the facts & figures behind the site.

Picture: GKN Wheels & Structures

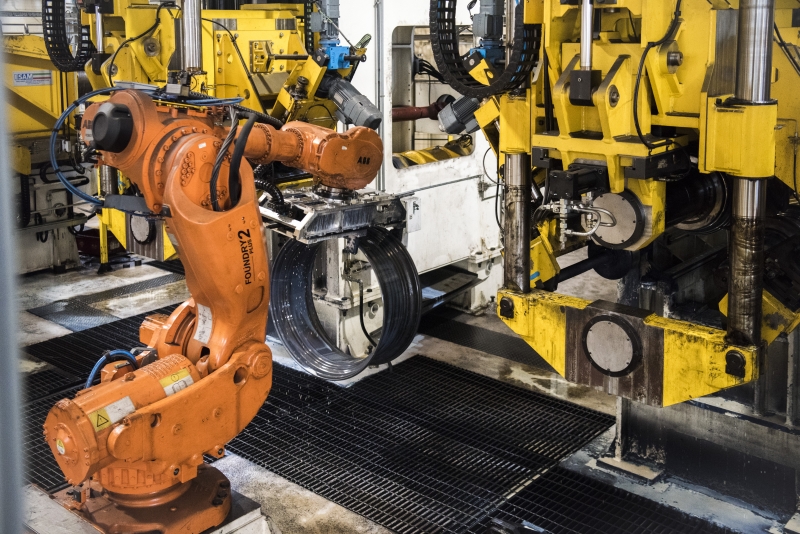

The multi-million pound investment project has delivered a completely new, state-of-the-art wheel manufacturing facility. The new production line was built in a separate location to ensure a seamless transition from the old line, which has now been decommissioned.

Picture: GKN Wheels & Structures

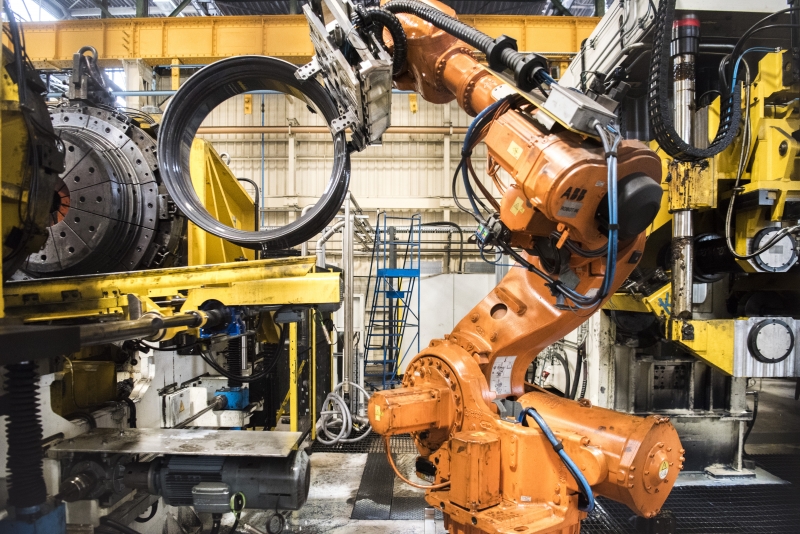

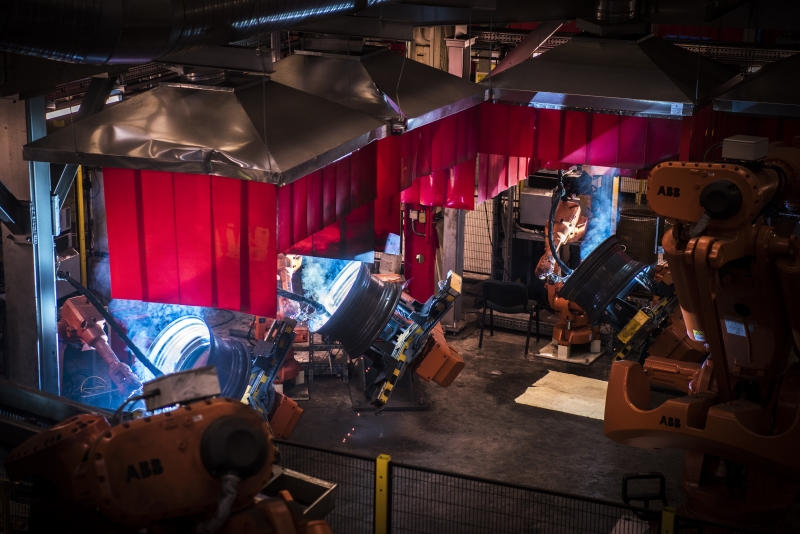

GKN Wheels’ Telford plant is now the most advanced, most modern wheel manufacturing facility in the world, with the investment including a new rim line, two robotic weld cells and a state-of-the-art powder paint facility.

Picture: GKN Wheels & Structures

The plant is currently manufacturing at a rate of more than 210,000 wheels per year, with capacity to increase this figure as required.

Picture: GKN Wheels & Structures

The investment project to install the most advanced rim manufacturing line for off-highway wheels included 87,000 contractor hours and 30,000 GKN Wheels core project staff hours.

Picture: GKN Wheels & Structures

The GKN Wheels Telford management team has over 125 years’ combined service, with the Head of Operations at Telford starting as an apprentice at the age of 17.

Picture: GKN Wheels & Structures

The wheel rim line and assembly cell are fully automated, with a total of 22 robots. There are also five CNC machines for disc manufacture (before the redevelopment, the plant had just five robots).

Picture: GKN Wheels & Structures

During the manufacturing process there is no manual intervention on the rim line or the assembly cell; loading and unloading material is the only manual element of the process.

Picture: GKN Wheels & Structures

Innovation: The Telford site works with the company’s two R&D centres in Italy and USA. A continuous cycle of improvement and information exchange between all the R&D and manufacturing teams provides a focus on process efficiencies, the effect of material changes, production cell efficiencies and improvements in welding and surface finish.

Picture: GKN Wheels & Structures

GKN Wheels manufactures and supplies off-highway wheels for the agriculture, mining, construction and material handling equipment sectors.

Picture: GKN Wheels & Structures

Embracing digital: The assembly line utilises real-time monitoring in a digital format, with end-of-line information points for all of the main site processes.

Picture: GKN Wheels & Structures

As part of the re-design of the rim line, an innovative tool changeover process was developed, enabling tool changeover times to be reduced by up to 88%. This has led to increased productivity and line efficiencies, as well as minimising downtime.

Picture: GKN Wheels & Structures

The team at GKN Wheels Telford actively collaborates with local colleges and educational establishments, building on its long-standing relationships with TCAT, Wolverhampton University and Harper Adams, as well as supporting local schools with STEM initiatives and learning.

Picture: GKN Wheels & Structures

From the first weld through to the final paint coat, wheel production is now three times faster than before the redevelopment.

Picture: GKN Wheels & Structures

GKN Wheels has been producing wheels in Telford since 1910 – customers can choose between 481 derivatives of complete wheels and 42 colours.

Picture: GKN Wheels & Structures

Primary customers include JCB, CNH, John Deere, Kubota and Claas. Based on 2020 volumes, approximately 25% of all wheels manufactured at Telford plant stay in the UK with the remainder being exported to Europe.

Picture: GKN Wheels & Structures

Featuring wheels designed and manufactured by GKN Wheels in Telford, in 2019 the JCB Fastrac Two became the fastest tractor in the world. Driver Guy Martin set a new world record, achieving a peak speed of 153.7711 and an average speed of 135.191 mph.

We would like to ‘See Inside’ your factory and share some insight about the investment, growth and future plans you have – if you wish to be featured, please get in touch on hello@zenoot.com