4 minute read

See Inside: The ZF production facility in Peterlee

ZF’s Peterlee facility is one of only three locations in the world that produces high-tech camera technology for ZF – with a large portion of production based here. The facility first opened in 1996 and has grown to be one of the largest employers in the North East region.

Picture: ZF Group

ZF Peterlee has become one of the most advanced manufacturing facilities in the European auto industry – and most productive. They currently manufacture around 9,000 automotive cameras every day. This will increase to 10,000 in 2019 when ZF introduce the latest state-of-the-art camera – S Cam4. Car companies will use its advanced object recognition capabilities to perform more complex tasks associated with automated driving.

Picture: ZF Group

ZF’s Peterlee facility has a long history of manufacturing safety systems for cars and currently produces 15 different product lines to the automotive market. Two of the major products are Airbag Control Units which have been made there since 2005 and state-of-the-art cameras for cars and trucks.

Picture: ZF Group

ZF has invested £40m (€46m) in the plant over the last few years. Products from this facility are supplied to many of the world’s biggest and best known automotive brands.

Picture: ZF Group

Despite highly automated production, the workforce has increased steadily from 450 in 2011 and is expected to reach 1,000 by end of 2019.

Picture: ZF Group

ZF is developing the technologies that enable cars to see, think and act. At Peterlee, they make those ‘see’ technologies viable in mass production – and to the highest quality standards anywhere in the world. When making safety electronics, quality and productivity must be cutting-edge.

Picture: ZF Group

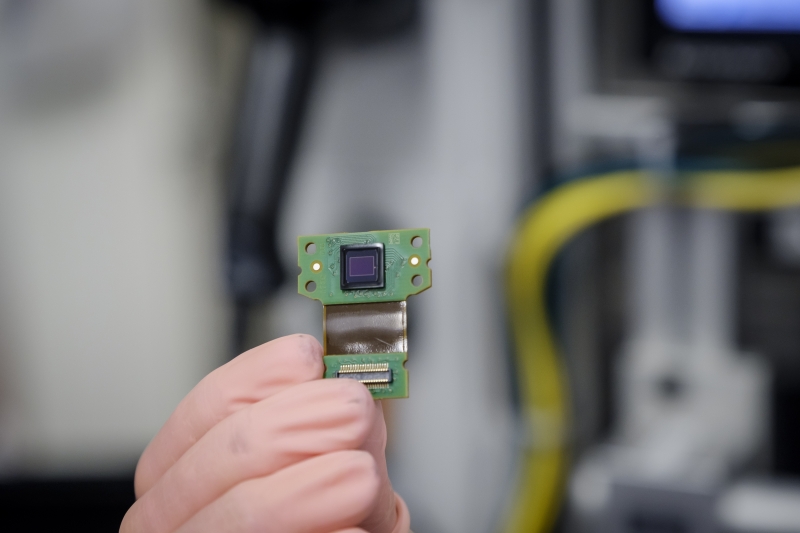

The camera technology, made at Peterlee since 2013, is crucial to the support of today’s advanced driver assist systems, such as assisted emergency braking, lane departure detection and pedestrian warning and will support the autonomous driving functions of the future. The technology helps to save lives all over the world.

Picture: ZF Group

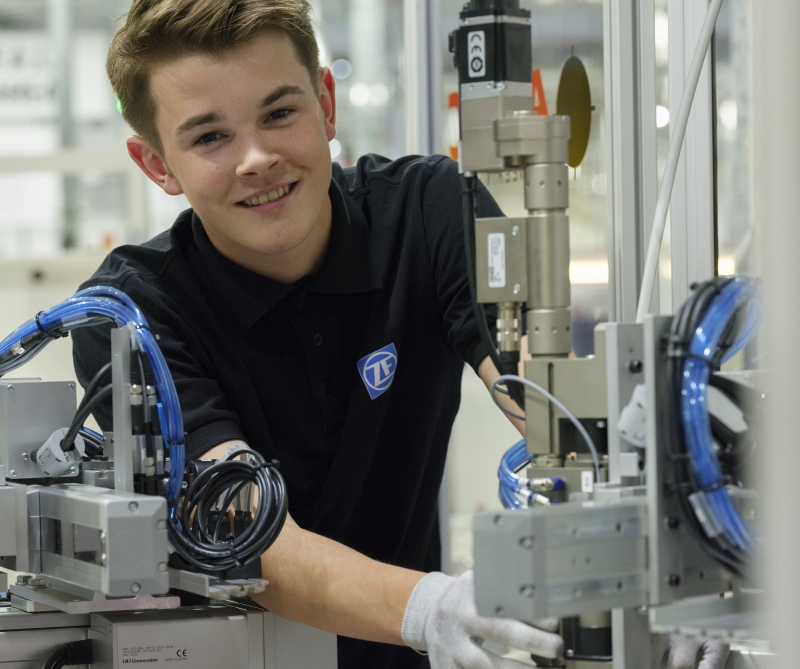

ZF’s re-launched apprentice scheme began in 2015 and attracts the brightest and most capable people in the region, giving them the skills and expertise to drive the business forward. ZF work with the local universities and colleges, offering student placements and apprenticeships. Two of their earliest apprentices have just been taken on as full-time employees.

Picture: ZF Group

To support that ethos, ZF has committed significant resources into an apprenticeship recruitment programme to ensure they consistently bringing enthusiastic young people into ZF – the next generation of talent who share the company’s ambition for long-term growth.

Picture: ZF Group

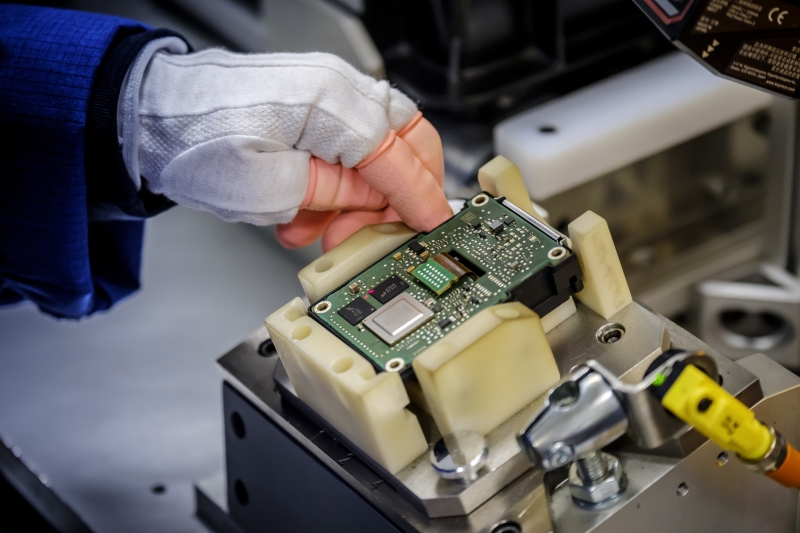

Due to the delicate and important safety functions housed in these units, employees wear special clothing and anti-static shoes and gloves to protect the components during the process.

Picture: ZF Group

The people at ZF Peterlee, taking care of business on the shop floor, are among the most highly trained in the industry. They not only operate the systems and equipment but develop programmes to improve performance.

Picture: ZF Group

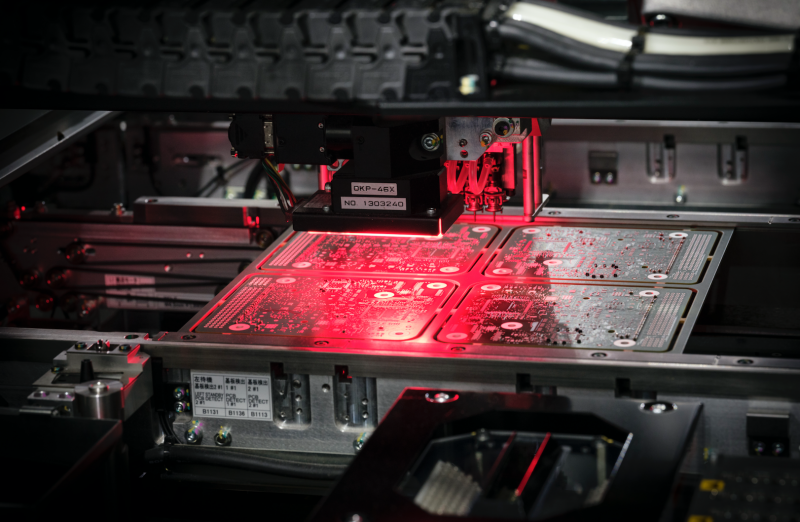

Manufacturing a camera for a car is not like making a camera for a smartphone. Automated vehicles require highly automated production processes to achieve greater levels of quality, durability and reliability.

Picture: ZF Group

The 3D camera at the end of the PCB line, known as AOI (Automated Optical Inspection), checks that all components are placed as expected on the PCB with exceptional accuracy, using programs developed by the local engineering team in Peterlee.

Picture: ZF Group

Each camera is calibrated and tested before leaving the factory. Each unit must pass 523 individual test processes before it can be released. The pass rate is 98-99%! These are not like ordinary digital cameras: they must meet industry standards for functional safety, work for many more years and operate in far tougher environments.

Picture: ZF Group

Working in a cutting-edge technological environment, apprentices can develop world-class maintenance and engineering skills within ZF’s Global Electronics Division.

We would like to ‘See Inside’ your factory and share some insight about the investment, growth and future plans you have – if you wish to be featured, please get in touch on hello@zenoot.com