5 minute read

The story of one graduate’s journey into engineering

Manufacturers across the country are always on the lookout for the next top quality candidate to fill a bit of their skills gap, the next apprentice, the next graduate, the next future leader even.

Much has been discussed around how manufacturers can collectively do more to make the sector as appealing as possible but we wanted to find out more from the other side, to see if manufacturers can learn from a graduate’s experience in starting a career in the sector.

Zenoot spoke exclusively to Colin Webb, a Product Design Engineering graduate from Brunel University, to talk about life after graduation and the transition to working in industry.

Can you give a little background to your experience at university?

I graduated from Brunel University in 2014 with a 2:1 BSc Honors Degree in Product Design Engineering. It was a great course as it gave me a true insight into what to expect in the industry and didn’t restrict my creativity. During my time at Brunel I was exposed to a variety of opportunities which I believe has set me up well in my role today.

One of the core reasons I chose this course was the range of activities on offer. Studying the mechanics, electronics, materials and manufacturing modules were my favourite. The course enabled me to learn about graphic design and the more artistic parts to design too. It was great to gain these additional skills as they have come in handy with my work today. In short, the experiences I have gained during my course have given me a great insight into what to expect in the industry.

Why did you choose the university you studied at?

Brunel University has strong industrial links and whilst I was studying there, we regularly received design briefs from real life companies. It was a fantastic opportunity to work with the university’s industrial partners and be as creative with ideas as possible.

Brunel helped set me up for life with invaluable support offered in their career centre, which aimed to help students transition smoothly from education to the workplace. In my second year of university, I completed a module with the centre and a lecture called Professional Practice, which provided valuable assistance on laying out a portfolio, preparing for an interview and writing a CV.

The module was really helpful in terms of gaining real world business information. The careers centre later helped me find and attend my placement opportunity with Owen Mumford.

Colin secured a placement at Owen Mumford whilst studying and then went on to work for them as a Design Engineer / Picture: Owen Mumford

Can you explain the process during transitioning from being a student to becoming a graduate working in the engineering industry?

The careers centre was a service that I only had to use the once. The placement application process required a CV, portfolio, cover letter and interview. Within my portfolio, I showcased a project I had completed with Finite Element Analysis (FEA) – a software engineering tool – which gave an example of my capabilities using the software. The interviewers at Owen Mumford liked this piece of work so much, that I later found out it was one of the things that clinched the deal in my hire. Lastly, the interview included a presentation of my work, a design challenge and a general discussion with an informal personality test at the end. During my final year of university, I was offered a full-time position at Owen Mumford to join the Junior Development Plan, which I went on to accept.

I learned multiple skills at Owen Mumford whilst on my placement year which included learning about the manufacturing process and preparing engineering drawings (geometric dimensioning and tolerancing). This was not on my course syllabus at Brunel so it was great to learn more about this whilst working in the industry.

One challenge I faced during my placement was getting to grips with the business dynamics and being in a network of collaborators. At university I worked very much individually so working in a network was very different and something new that I had to learn and adapt to. Although this was a new way of working, it was a change that I very much enjoyed and it is now one of the parts of my job that I thrive off the most. General creative thinking is always promoted at Owen Mumford and luckily this is something I really enjoy. With creativity, you see through a design to a working product. It is very rewarding!

What experiences could you share with other manufacturers to inspire them to embark on graduate programs of their own?

The Junior Development Plan at Owen Mumford is valuable as it provides students with the chance to try their hand at new skills. Owen Mumford is a very supportive company and development is available and encouraged to all employees. The Junior Development Plan has been created to give graduates a series of targets to meet during their time here, to ensure they progress. From the Junior Development Plan, I have now moved into a Design Engineer role and I now help other graduates to develop, so I’ve gone full circle.

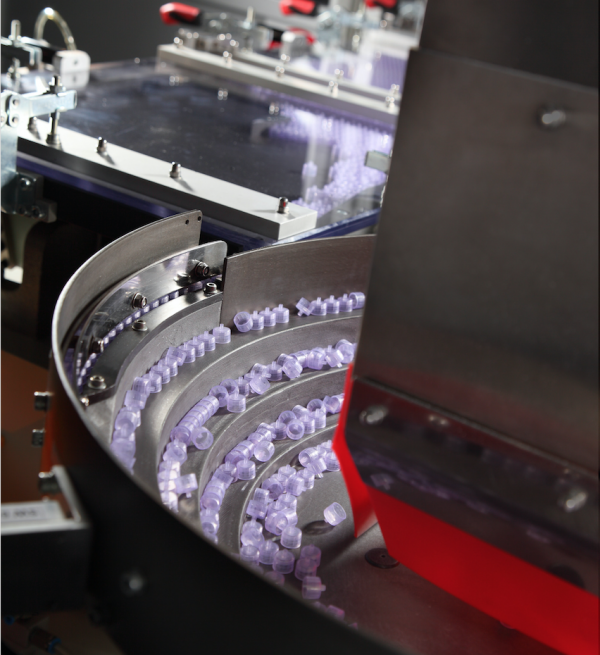

Owen Mumford develop and manufacture a range of medical devices / Picture: Owen Mumford

What advice would give graduates looking to embark on a career in manufacturing or engineering?

For recent and future graduates, a piece of advice I have is that you should spend a lot of time working on your portfolio and CV. In an interview, this and your personality are the key things you can shine with. Employers need to see what your personality is like – are you friendly, a team player, someone who would collaborate well within the company? All of these attributes are equally as important as the technical ability you display in your portfolio at the interview.

My placement experience at Owen Mumford was invaluable in providing additional experience and ultimately made me want to work for the company after graduating. Who wouldn’t? As for the future, the main thing I enjoy is being creative, not only in my job but in life, so I’m looking to develop my skills further in every way I can. I’d also like to continue to teach graduates and collaborate with others. I find it a very fulfilling process!

Design Engineer, Colin Webb / Picture: Owen Mumford

About Owen Mumford

Colin now works for Owen Mumford, a major medical device manufacturer that develops pioneering medical devices for its own Owen Mumford brand and custom device solutions for the world’s major pharmaceutical and diagnostic companies.