5 minute read • published in partnership with CREAT3D

Case Study: Fastlane Turnstiles transforms its entire business workflow with additive manufacturing

Fastlane Turnstiles has transformed its entire business workflow with additive manufacturing to deliver bespoke high-quality security systems.

Fastlane Turnstiles is a brand of pedestrian entrance control, wholly owned by Integrated Design Limited (IDL), which was formed in 1985. Based in Feltham, near Heathrow, IDL has its own manufacturing premises and HQ onsite which is further expanding in 2021.

IDL design and manufacture high-end security products and solutions for entrance control of buildings. The company’s key brands, Fastlane Turnstiles and Door Detective (anti-tailgating products), help to secure a large number of the world’s most notable and highest security buildings. IDL has a global range of clients in Banking & Financial, Education, Utilities and Healthcare facilities, including Facebook, Dell, Microsoft, Google, Fidelity Investments, Uber and Adobe.

Entrance control products are constantly evolving, and Fastlane is best positioned to deliver to the unique requirements for each client by tailoring the end product. With over 70% of Fastlane’s end products featuring a bespoke element, this is where additive manufacturing plays a key role.

Additive manufacturing now plays a key role in Fastlane’s products / Picture: Integrated Design Limited/CREAT3D

Bespoke design requires a highly tuned workflow

Fastlane operates in a constantly evolving industry, with security products developing at a fast pace, with new advancements in identification processes. Over 70% of Fastlane’s end products have a bespoke element to them, including tailored aesthetics. Whilst core components cross-over in the range of entrance systems, there is a huge requirement to integrate different card readers, tokens or biometric systems into the end product to generate a personalised aesthetic and function. As a client’s identity becomes even more unique and important, so does the need to have branded and unique access control systems designed to match.

Integrating Additive Manufacturing into Fastlane’s workflows has enabled the team to develop and maintain a competitive advantage. Many competitor solutions use mass-produced or off-the-shelf products, without the adaptability to create bespoke products for clients.

AM is now involved right at the beginning of design and production process at Fastlane. Tony Smith, Marketing Manager, explained: “Before we used to estimate a product and do an outline drawing for customer approval. Now we do the full design brief, so we know the design we are going to make and how we are going to make it before we offer it to the client for approval”.

This change in workflow ensures that Fastlane can be sure they can deliver a high quality, bespoke product to the client and quickly. Upon receiving the initial design specification, concepts will be iterated and sent to the client for approval. As part of the iteration process, the design is sent to Production to set the production processes, whereby any requirement for components, mountings or jigs are 3D printed in advance.

Mike Lau, Technical Manager, said: “The good thing is because we have completed the full design up-front, with all the componentry, parts for assembly and have assembled a test part, we understand what is required to produce the part. When it does come to production there are a lot fewer issues we need to sort out. In the past, we would have seen more problems in production, time lost with shipping delays or component fitting which would have compounded, but now this is all addressed beforehand”

This efficient and comprehensive workflow allows Fastlane to build to order within 8 to 10 weeks.

The applications for additive manufacturing have snowballed

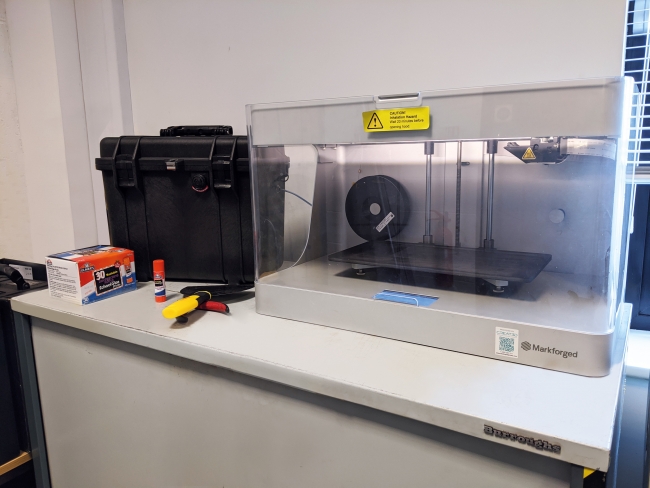

The Mark Two 3D printer is located in the Engineering Office, with the Engineering and Design teams having continual access to the technology to respond to client design briefs and develop new products, and for the production teams to send requests for the development of production aids. The ethos of the company is for everyone to work very closely together, which means that changes can be made rapidly and departments can react very quickly.

The initial reason for purchasing a 3D printer was for R&D. Fastlane wanted to improve internal processes, reducing costs and increase the speed of development. Surface finish and strength were important criteria in selecting the right type of Additive Manufacturing equipment, and working closely with CREAT3D, the Markforged 3D printer was recommended and selected.

Now, the range of applications has snowballed, and Fastlane has seen huge time & cost savings.

Mike added: “The Markforged has changed the way we design. There are now no limitations. In the past, we have been constrained by the traditional methods of manufacturing of machining, turning and sheet metal, but with Additive Manufacturing, it’s really changed the way we think about design and what is achievable”

Engineering and Design teams having continual access to the technology to respond to client design briefs and develop new products / Picture: Integrated Design Limited/CREAT3D

As a result of embedding the Markforged Mark Two, Fastlane has completely re-defined its business processes, from sales, to quoting and pre-production, through to design, production and assembly, with a direct result on its clients being able to receive more tailored solutions, and faster.

• Engineering Design has changed the design workflow, to foresee any production issues before client sign off

• Clients receive more tailored, and previously unattainable products through bespoke 3D printed end parts

• R&D has more freedom to experiment with design & develop new products, faster and at lower cost

• Production processes are defined before a project starts with any custom jigs, tools, mounts and production line fixes 3D printed immediately

Bespoke end components

One client wanted to integrate Hitachi’s USB Finger Vein Biometric Authentication Unit into their entrance control systems, to take a biometric scan of the user’s finger to grant access. As the product itself was newly developed, there was no existing way to mount the unit to the turnstile.

By fitting a 3D printed housing, Fastlane was able to manufacture a complete set of entrance systems using the unique access control, that previously could not have been manufactured. The part was produced in Onyx material (Nylon with micro carbon fibres) which is both functional and aesthetically pleasing.

Cost and time savings example of a bespoke end product

Traditional Fabrication

This product was cost and time prohibitive to manufacture.

Using Additive Manufacturing

A bespoke housing was 3D printed in Onyx and fitted to the end turnstile. No additional finishing required.

• Production time > 12 hours

• Production costs > £10 per unit

By embedding 3D printing, Fastlane has completely re-defined its business processes / Picture: Integrated Design Limited/CREAT3D

Faster R&D

Using the Markforged 3D printer allows the Engineering Design team to experiment with design, developing iterations rapidly at reduced costs and timescales. Carbon Fibre is commonly used in R&D parts, especially in components attached to moving parts, or clamps & shafts that require strength from the reinforcing fibres. The parts are 3D printed and validated, before proceeding to tooling.

R&D projects designed to develop product and check fit and functionality are now achieved a lot quicker, removing the need to manage external suppliers, and keeping knowledge and proprietary information in-house

Cost and time savings example of the R&D of a rotary part

Traditional Fabrication

This would previously have been outsourced, machined out of steel with a one-off cost of £300 on a 2 week lead time, with restrictions to the part design because of the method of manufacture. Once the part was received, it would need to be checked and validated.

Using Additive Manufacturing

Changing the part development to in-house on the Markforged, Fastlane are able to print the part in under 4 hours, at a cost of £10, with no post-processing. If iteration is required, it can be immediate, providing a low cost of failure

Bespoke parts at a reduced cost, with enhanced design and production workflow

Having integrated the Markforged Mark Two into Fastlane’s products, there has been a multitude of benefits; the workflow from design to manufacture is faster, leaner and more efficient, Production are receiving aids quicker, the Sales Team have more scope to tailor client projects and clients are receiving unique products.

The future of Fastlane’s products and solutions will continue to evolve, with additive manufacturing at the heart. The immediate future will see a continuation of bespoke end components and batch production of parts, continuing to support production and design teams. The use of AM for 3D printing metal components and moulds will also increase. “We can print really complicated components to check feature, fit and function. The 3D printer allows us to move away from traditional sheet metal, to bespoke components in other methods of production such as casting”, Mike Lau, Technical Manager.