Our top 12 UK manufacturing stories from 2019

Throughout 2019, we’ve published many positive stories from across the UK manufacturing sector. In a roundup of the last 12 months, we take a look back at our favourite and biggest stories from each month this year.

The top stories of 2019 are also featured in the UK Manufacturing Review 2019/20, an annual 250-page review of the year across the manufacturing sector including forecasts for 2020. The review is published and distributed by Stirling Media on 1 February 2020.

Now in its fifth edition, the UK Manufacturing Review (UKMR) is the essential annual source of information on manufacturing, in all its forms. The latest edition covers major sectors, from food & drink – the largest – to pharmaceuticals, the biggest R&D investor, and including headline-grabbing automotive and aerospace; the ‘quiet heroes’ of textiles and the burgeoning satellite industry; turbulent steel; innovative electronics; rail, marine and energy. New this year is a section on the niche, but valuable, watchmaking industry.

The UKMR looks across the nations and regions that make up the UK, from the South-East to Northern Ireland and Scotland. The ‘Technologies’ section covers the growing areas of additive manufacturing, modular construction and smart factories, as well as essentials like metrology and advanced materials.

The Manufacturing Technologies Association provides an in-depth preview of MACH 2020. ‘Inside the Factory’ looks at exemplar manufacturing operations. ‘Trailblazers’ highlights innovative and pioneering companies; a feature on the Future of British Manufacturing Initiative has case studies of successful adoption of digitised solutions.

“UK Manufacturing has been through a torrid year in 2019, with Brexit uncertainty, trade wars and inevitable economic ebbs and flows,” says Ruari McCallion, UKMR Editor. “But British manufacturers are nothing if not resilient and resourceful, as this year’s UKMR shows, once again. Finally, many thanks to our sponsors, without whom the book would be impossible.”

Supporters of UKMR 2019/20 include The Manufacturing Technologies Association, Autodesk, Sharing in Growth, IFS, Cranfield University, Irwin Mitchell, Metsoftpro and igus.

January

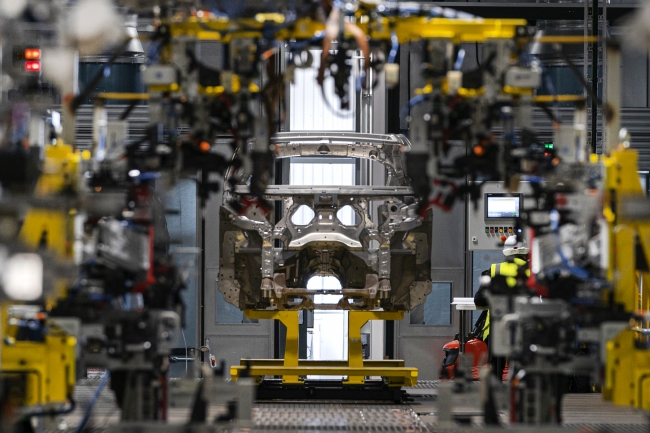

Toyota starts production of new Corolla models at UK factory

In January, Toyota officially started production of the all-new Toyota Corolla Hatchback and Touring Sports wagon at the Toyota Manufacturing UK (TMUK) car plant in Burnaston, Derbyshire, following a £240m investment programme in its UK manufacturing operations. TMUK is the exclusive European production centre for these new models, which will be strong contenders in the highly competitive C-segment compact hatchback and wagon market. At the time, Marvin Cooke, TMUK managing director, said: “This is a proud day for everyone at TMUK, making the new TNGA Corolla is a major milestone in our production history. This is a real sign of confidence in the capabilities of our workforce and in TMUK as a centre for world-class manufacturing.” The new Corolla is the first Toyota model in Europe to offer customers the choice of two hybrid powertrains: an upgraded 1.8 litre engine that is manufactured at the Toyota Deeside engine plant in North Wales, and a new powerful 2.0-litre hybrid powertrain.

Read more

February

INEOS to invest £1 billion in the UK

In February, INEOS announced it was to invest £1bn in the UK in multiple projects designed to ensure its British assets stay world-class for a generation. One part of the huge INEOS investment included a £350m investment at Grangemouth for the development of a new steam and power plant, delivering significantly improved energy efficiency and long-term reliability. In addition, INEOS will invest £150m in Hull to construct a new Vinyl Acetate Monomer (VAM) plant. This will bring production of an important raw material back to the UK. The third and biggest investment being announced is in the Forties Pipeline System (FPS). This £500m investment will transform the asset and extend the life of the pipeline by at least twenty years, into the 2040s. Opened in 1975, FPS is a strategic UK asset that can transport up to 600,000 barrels of North Sea oil onshore for refining every day. The pipeline transports 40% of the UK’s oil & gas to the mainland.

Read more

March

£50m C-ALPS centre opens in Coventry

In March, a £50m state-of-the-art facility for creating cleaner mobility opened in Coventry, giving a major boost to the UK automotive industry. The Centre for Advanced Low-Carbon Propulsion Systems (C-ALPS), a collaboration between Coventry University and global engineering specialist FEV Group, is looking to harness cutting-edge academic and commercial expertise to support the development of the next generation of electric, hybrid and combustion engines. Over 30,000 sq ft of purpose-built space will house some of the most advanced internal combustion and electrification testbed facilities currently available in the UK, creating a dedicated resource for testing current and future powertrain solutions quickly and efficiently. The capabilities will be available to OEMs, SMEs in the supply chain and technology partners keen to accelerate the creation of new propulsion systems for use across the automotive, aerospace, marine and rail sectors. 36 new jobs were created initially, with a number of apprentices and graduates from Coventry University already appointed.

Read more

April

Forterra to invest £95m at Desford plant following planning approval

In April, leading building products manufacturer, Forterra, confirmed it was set to commence a £95m project to double production capacity at its Desford plant, after the planning application for a new facility was permitted. The major investment promised to transform the company’s Desford facility in Leicestershire into both the largest and most efficient brick factory in Europe, whilst increasing Forterra’s overall production capacity and consolidating its role in the future of UK housebuilding. With a current output of 85 million bricks per year, the Desford plant’s production capacity is set to double in the next three years as a result of the investment to 180 million bricks annually – enough to build 24,000 average-sized family homes. On a company-wide scale, this will increase Forterra’s overall brick production capacity by 16%. This twofold increase in output will be achieved via the construction of a new, modern facility with automated processes that will minimise the plant’s environmental impact. The new premises will be built alongside the current factory, ensuring that the latter remains operational in order to maintain production during the changeover. Production is expected to commence in 2022.

Read more

May

McLaren Automotive marks building its 20,000th car

In May, McLaren Automotive celebrated the 20,000th car to be hand-assembled at its McLaren Production Centre (MPC) in Woking, Surrey. Later in the year, the firm also announced plans to double the size of its workforce at the Sheffield-based Composite Technology Centre. The 20,000th car to be built was a right-hand drive 600LT Spider in chicane grey from the brand’s Sports Series line-up. The milestone comes eight years after the first McLaren road car left the MPC in July 2011. While McLaren’s production reached just over 4,800 cars in 2018 to meet rising global demand, output will be maintained at around 5,000 a year into the next decade. McLaren Automotive now employs over 2,300 people and contributed a significant proportion of McLaren Group’s overall £1.2bn of revenue in 2018. The introduction of a second production shift in 2016 to meet rising global demand for McLaren vehicles has seen production double from around 10 cars to over 20 a day. Over 90 per cent of vehicles built in Woking are exported to more than 32 markets around the world.

Read more

June

Production starts at new Aston Martin factory in Wales

In June, Aston Martin Lagonda’s second UK manufacturing plant started to produce cars, as pre-production models of the luxury British carmaker’s first SUV, the Aston Martin DBX, were built. This story developed during 2019 with the DBX unveiled in November and the official site-opening taking place in December. The 90-acre former Ministry of Defence site at St Athan in Wales was announced as the second UK plant for Aston Martin Lagonda in early 2016 and since then the whole site, including three ‘Super Hangars’, has been transformed into a modern manufacturing facility for hand-crafted British cars. Forming part of Aston Martin’s continued investment in the UK, the opening of St Athan has so far created 200 jobs and is expected to create up to 550 more. St Athan is the sole production facility for the Aston Martin DBX.

Read more

July

Jaguar Land Rover confirms plan to build electric vehicles at Castle Bromwich

In July, Jaguar Land Rover confirmed plans to manufacture a range of new electrified vehicles at its manufacturing plant in Castle Bromwich as part of a £1bn investment. The company said the announcement was the next significant step in delivering on its commitment to offer customers electrified options for all new Jaguar and Land Rover models from 2020. The first new electric car to be produced at the plant will be Jaguar’s flagship luxury saloon, the XJ. The news was confirmed to workers at Castle Bromwich as production of the current XJ came to an end. The announcement, which safeguards several thousand jobs in the UK, is the next stage in execution of Jaguar Land Rover’s electrification strategy. In January, the company confirmed plans to bring battery and Electric Drive Unit (EDU) assembly to the Midlands with investment in new and existing facilities.

Read more

August

Coca-Cola European Partners invests £23m at Scottish factory, part of a £150m investment in 2019

In August, Coca-Cola European Partners (CCEP) confirmed a £23m investment at its East Kilbride operations, in what the company says is a demonstration of its ongoing commitment to manufacturing excellence and innovation in Scotland. But, coupled with significant investments at other sites, 2019 saw the company invest a staggering £150m across the country. Since 2010, CCEP’s ongoing multi-year investment programme has reached a total of £650m in Great Britain.

Read more

September

INEOS Automotive confirms Grenadier 4X4 to be built in Wales

In September, INEOS Automotive announced that its utilitarian 4×4 will be named ‘Grenadier’ after the pub in which it was conceived, with over 6,000 international fans and followers responding to an online poll to choose the vehicle’s name. INEOS also confirmed that the Grenadier will be built in a bespoke new manufacturing facility on a greenfield site in Bridgend, South Wales. This will create 200 jobs initially, and up to 500 in the long term. Site development commenced immediately to support the planned start of production in 2021. INEOS Automotive also said that in parallel, it will be investing in a sub-assembly plant in Estarreja, Portugal. The facility will produce the Grenadier’s body and chassis, working in conjunction with INEOS’s European supply chain partners.

Read more

October

Green light for new £120m Wren Kitchens manufacturing site

In October, Wren Kitchens secured approval from North Lincolnshire Council for the development of a £120m state-of-the-art kitchen manufacturing facility located behind its existing factory on the Barton-upon-Humber 180-acre estate. As reported in June, the 990,000 sq ft development is Wren’s largest single investment and it will be a major boost to the UK economy bringing with it up to 1,200 multi-skilled job opportunities in not only manufacturing but also IT development, engineering, customer service and product development. From opening its first showroom 10 years ago, Wren has grown to become the UK’s largest kitchen retailer with 83 showrooms nationwide, and a further five opened this year.

Read more

November

£2.8bn armoured vehicle contract awarded to Artec consortium

In November, the Artec consortium, led by Rheinmetall and Krauss-Maffei Wegmann, signed a contract with the UK Ministry of Defence to produce more than 500 Boxer 8×8-wheeled armoured vehicles for the British Army. It followed the announcement in January 2019 that BAE Systems and Rheinmetall had agreed to create a joint UK-based military vehicle design, manufacturing and support business. Most of the production will take place in the UK, safeguarding and creating a substantial number of British jobs. Full-scale production will begin in Germany, but 90% of the Boxer vehicles destined for the British Army will be produced in the UK, principally at plants operated by Rheinmetall BAE Systems Land (RBSL) and WFEL, a subsidiary of Krauss-Maffei Wegmann. The Boxer vehicles will be supplied in several different configurations, including an armoured personnel carrier, command vehicle, specialist carrier and field ambulance. Delivery of the vehicles is expected to start from 2023.

Read more

December

RB confirms £200m UK investment commitment

In December, RB – formally known as Reckitt Benckiser – opened its new £105m state-of-the-art Science and Innovation (S&I) Centre in Hull. The S&I Centre, with brand new consumer health laboratory facilities, is the first milestone of RB’s ongoing £200m investment programme in the city. Alongside the new centre, the global consumer health and hygiene company is committing a further spend of £95m to significantly upgrade its manufacturing facilities on the Hull site, which currently employs around 1,400. As well as this site investment, RB is partnering with Hull York Medical School and the University of Hull to offer a brand-new MSc in Pharmacology and Drug Development.

Read more